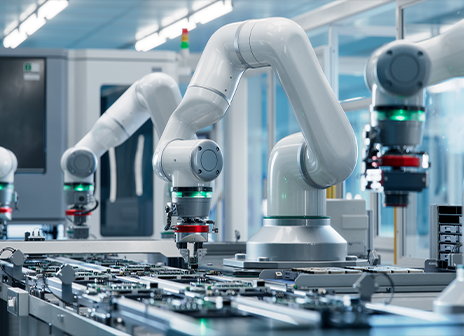

The Indian manufacturing sector is undergoing significant transformations due to evolving skill requirements, government policies, technological advancements, and global trends. Skill development in manufacturing is crucial for job creation and empowering the younger generation. Programs in mechatronics, software engineering, and advanced techniques enable young individuals to excel in the sector.

Prioritizing skill development can help India achieve its manufacturing goal, contributing 25 percent to its GDP.

"Plus One" Strategy in Multinational Manufacturing

- Mitigates risks of overdependence on a single country

- Lowers labor and production costs

- Enhances resilience and agility in response to market dynamics

India's Manufacturing Potential

- Large trainable workforce

- Digital infrastructure for efficient operations

- Investments in logistics infrastructure

- Proximity to various countries for supply chain diversification

- Strategic location for accessing emerging markets

- Low-cost manufacturing with robust legal infrastructure and patent protection mechanisms

India's manufacturing sector has significant potential for growth due to efficient supply chains, cost-effectiveness, design-oriented approaches, and technological advancements. With its advantageous location, large labor force, and focus on innovation, India can capitalize on emerging global prospects. Investing in digital technologies like IoT, AI, blockchain, and advanced manufacturing technologies is crucial for operational optimization.

In a nutshell, India's manufacturing sector is undergoing significant changes due to shifting skill sets and global impacts. Its growth potential lies in GDP, employment, and export performance. To seize emerging opportunities, India should prioritize supply chain efficiency, cost-effectiveness, design-led approaches, and technological advancements. Innovation, research, skill development, and design-led manufacturing are crucial drivers.